Innovations

Dilution valves for the dilution of concentrated products

An innovative solution for protection from dangerous concentrated products and for environmental protection.

Use

Chemical industry

Thanks to new biocidal legislation, it is no longer possible to get permission to place on the market biocidal products that are classified as corrosive or hazardous in other ways. Products whose packaging completely eliminates any direct contact between the user and the corrosive product during dilution are an exception. It can also be applied to products that are not subject to the Biocidal Products Regulation (REACH).

Food industry

If a manufacturer is looking for an innovative way to market new types of products or a way to reduce transport costs, dilution valves are the right solution. Pouches are made of hygienic materials that are normally used as food packaging.

Pharmaceutical industry

Wherever it is desirable to dilute concentrates in a fully hygienic manner (hospitals and other health facilities).

Types of dilution systems

A system with partly limited access to the concentrated product

A suitable solution for professional users who need to reduce exposure during the authorisation mode; in the case of less dangerous products, it can also be used by non-professional users. This has applications in the food industry for mixing drinks or raw materials.

A system where access to the concentrated product is fully limited

A suitable solution for non-professional users of hazardous biocidal products. For example, products classified as corrosive cannot be authorised or marketed without this solution.

Advantages

- An innovative solution and innovative product design

- It allows the continued marketing of products that are corrosive and hazardous in other ways

- It protects human health

- It protects the environment - there is no transport of water by trucks

- It reduces transport costs

- It does not require additional solutions that prevent children from opening the package

- For both the professional and non-professional user

- Free regulatory consultancy and services related to the inclusion into IUCLID dossiers according to BPR

Calculate how much fuel and CO2 you can save by transporting concentrated preparations

Calculating saved CO2 (carbon footprint)

Calculating saved fuel

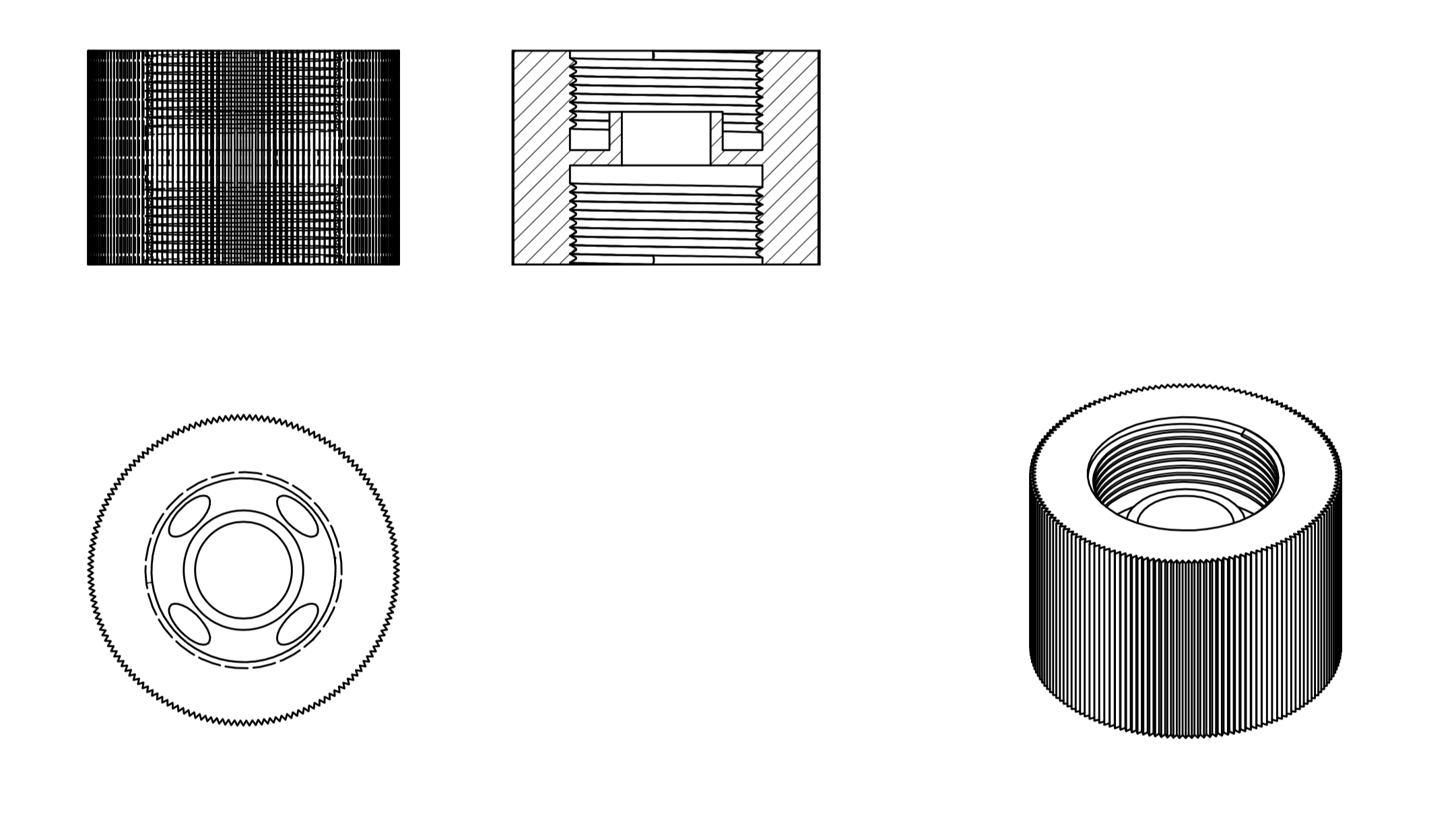

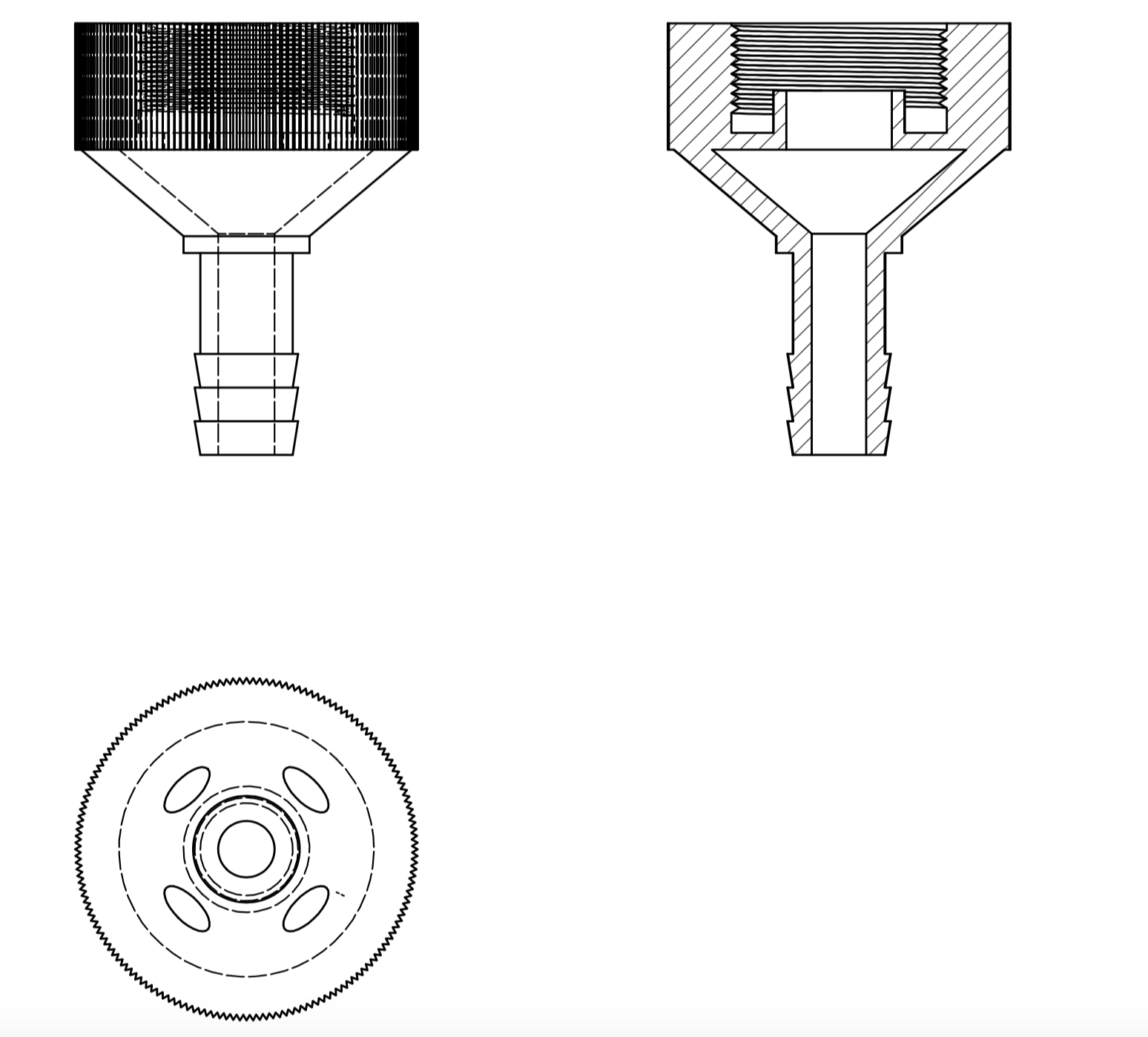

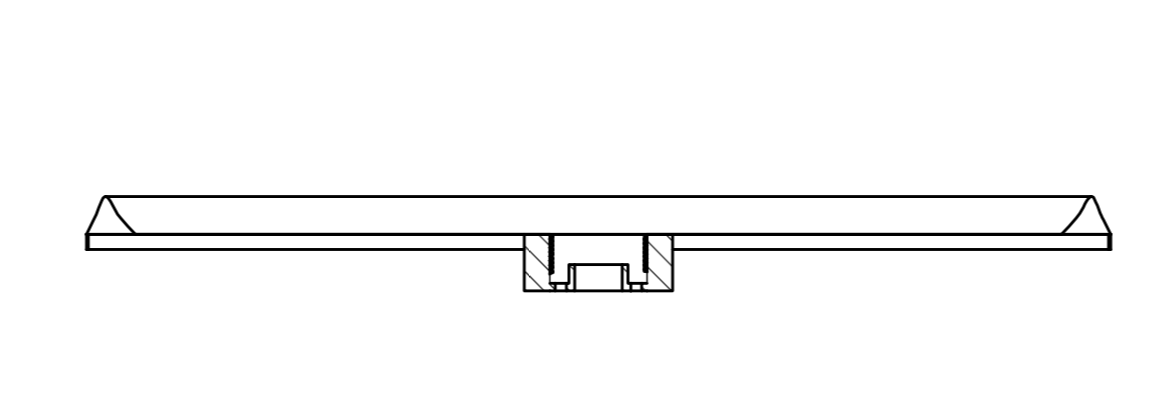

VAR 1.1 to DV basic - used for dilution concentrates in a standard PET bottle. The concentrate container is equipped with a membrane, to which there is unrestricted access after the lid has been unscrewed. The advantage is that the costs are low and a second container does not have to be supplied with the packaging. It has applications in both the food and chemical industries.

VAR 1.2 DV for containers with remote access - the solution is particularly advantageous for suppliers of packaging where handling is difficult, or in areas where there is limited access to the dilution container. It is mainly used in the chemical industry.

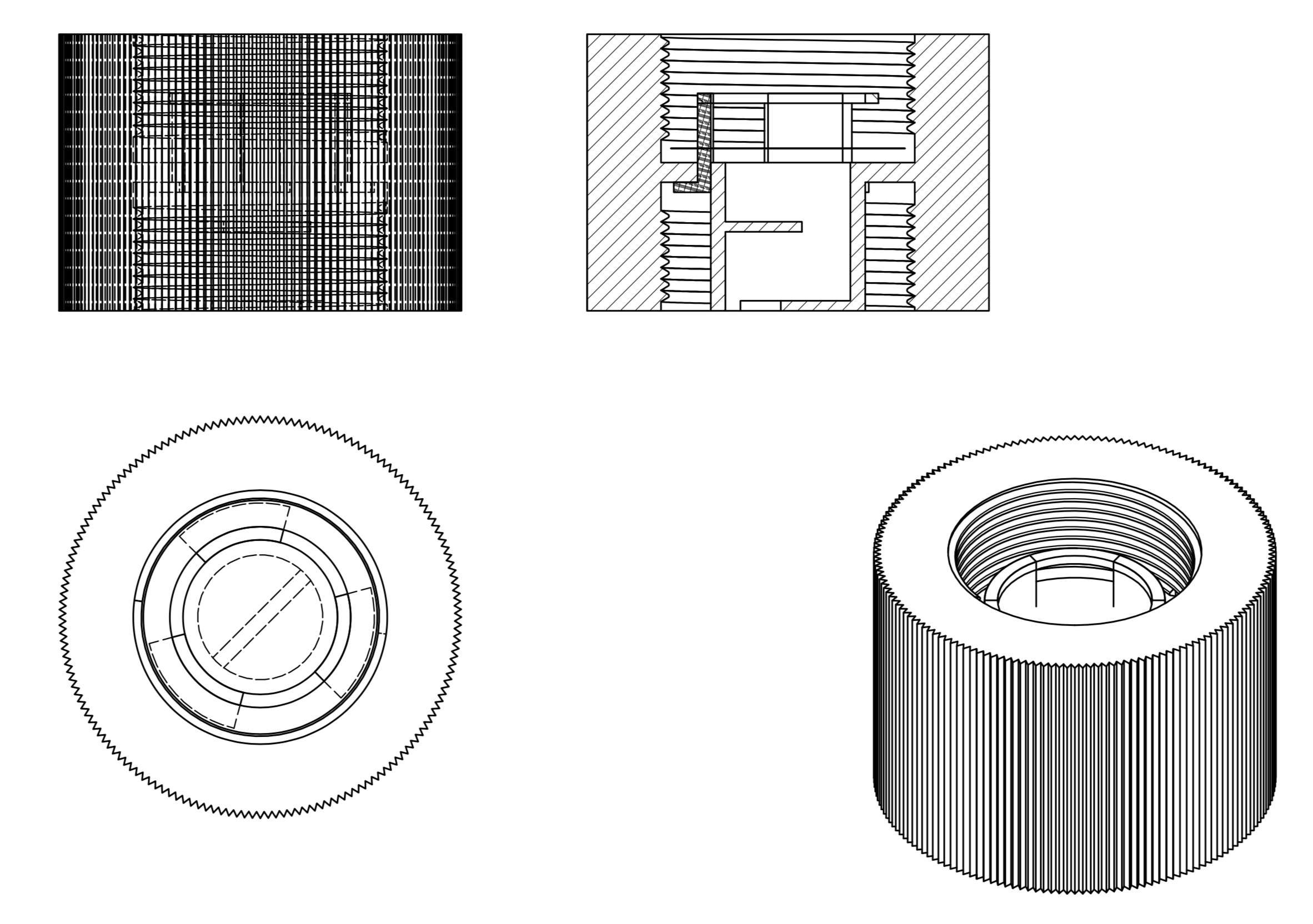

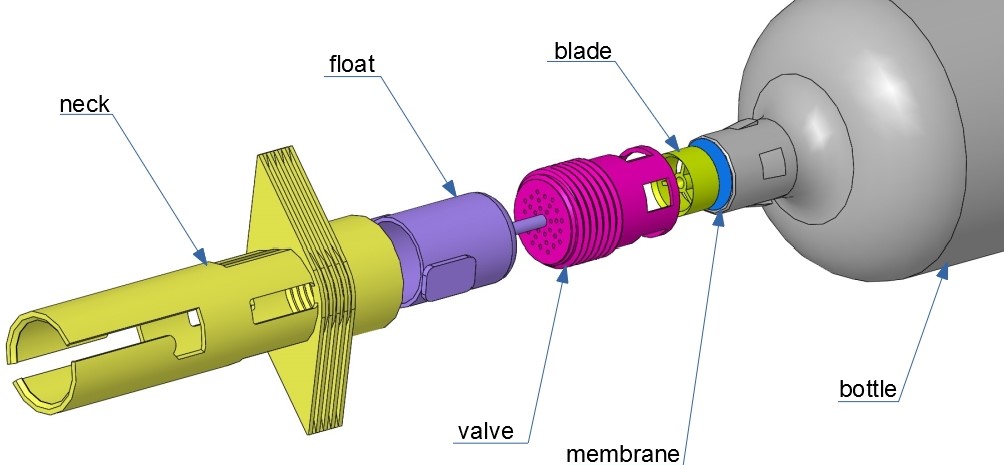

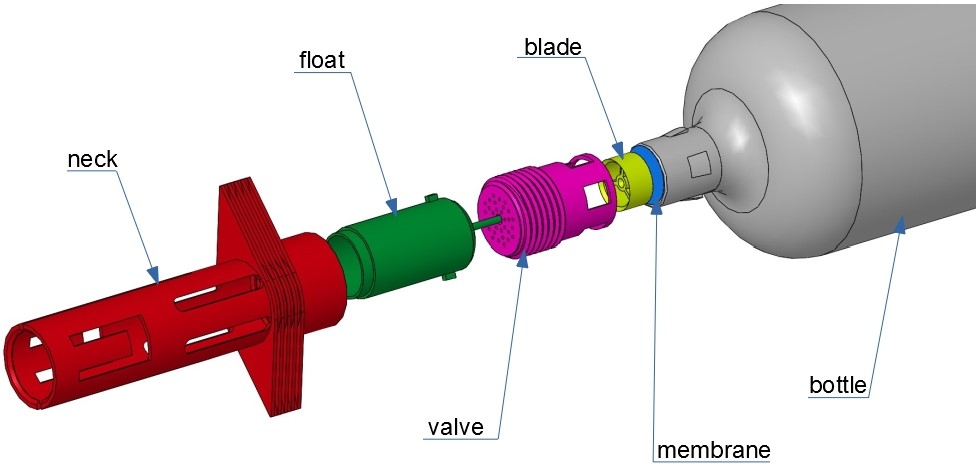

VAR 1.3 DV with an internal knife - a solution where it is desirable for the user not to have access to the membrane that protects the concentrate. The membrane is protected by a set of overlapping baffles, around which a peripheral knife is placed. The knife cuts through the membrane at the moment when the PET bottle is screwed into the valve, or the valve is connected to a larger container. It is mainly used in the chemical and pharmaceutical industries.

VAR 1.4 DV for large containers - this simple yet effective solution can be applied by industrial users in particular. The dilution valve can be fastened to any container, e.g. to the lid of a bucket, barrel or IBC container.

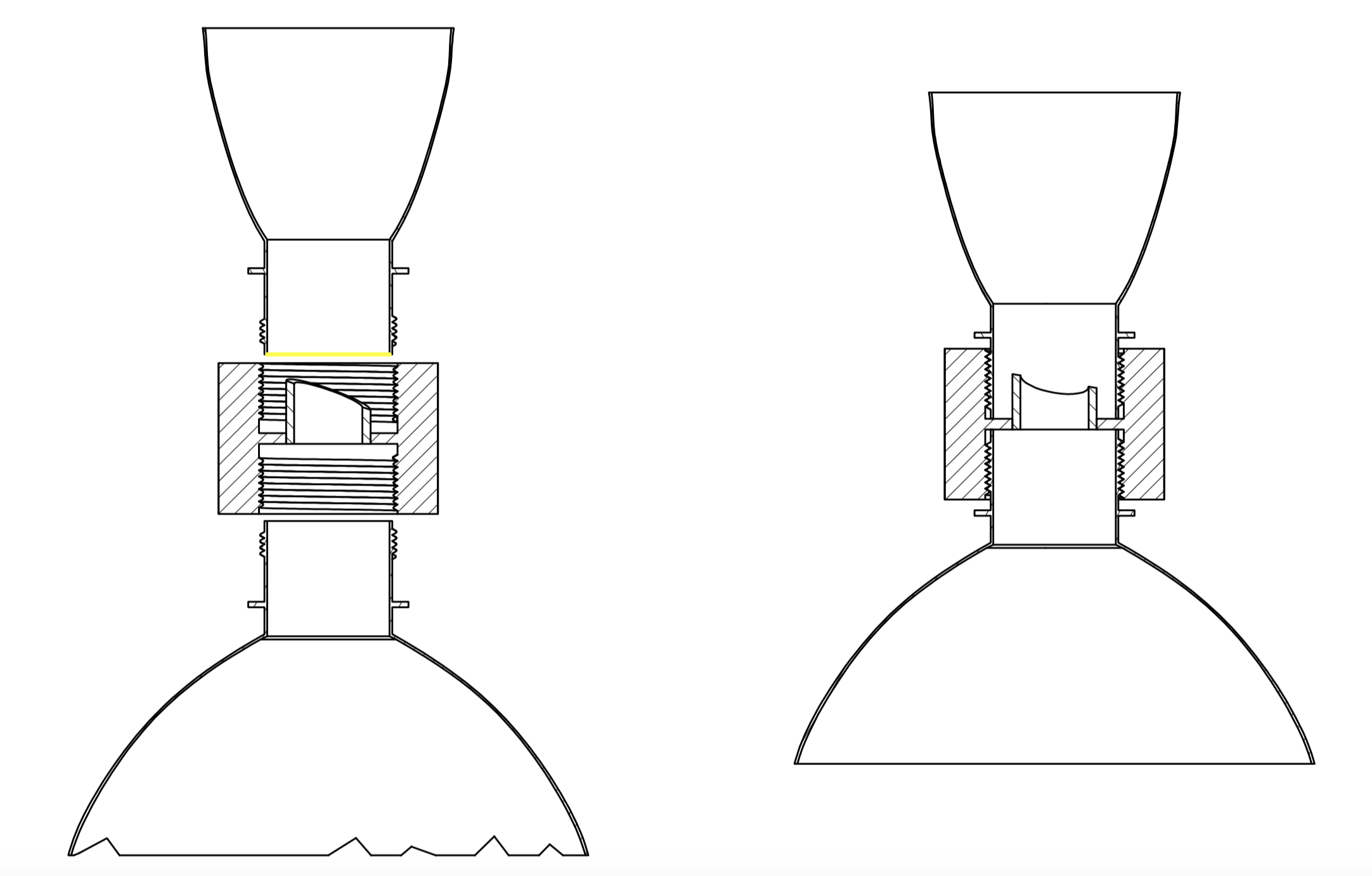

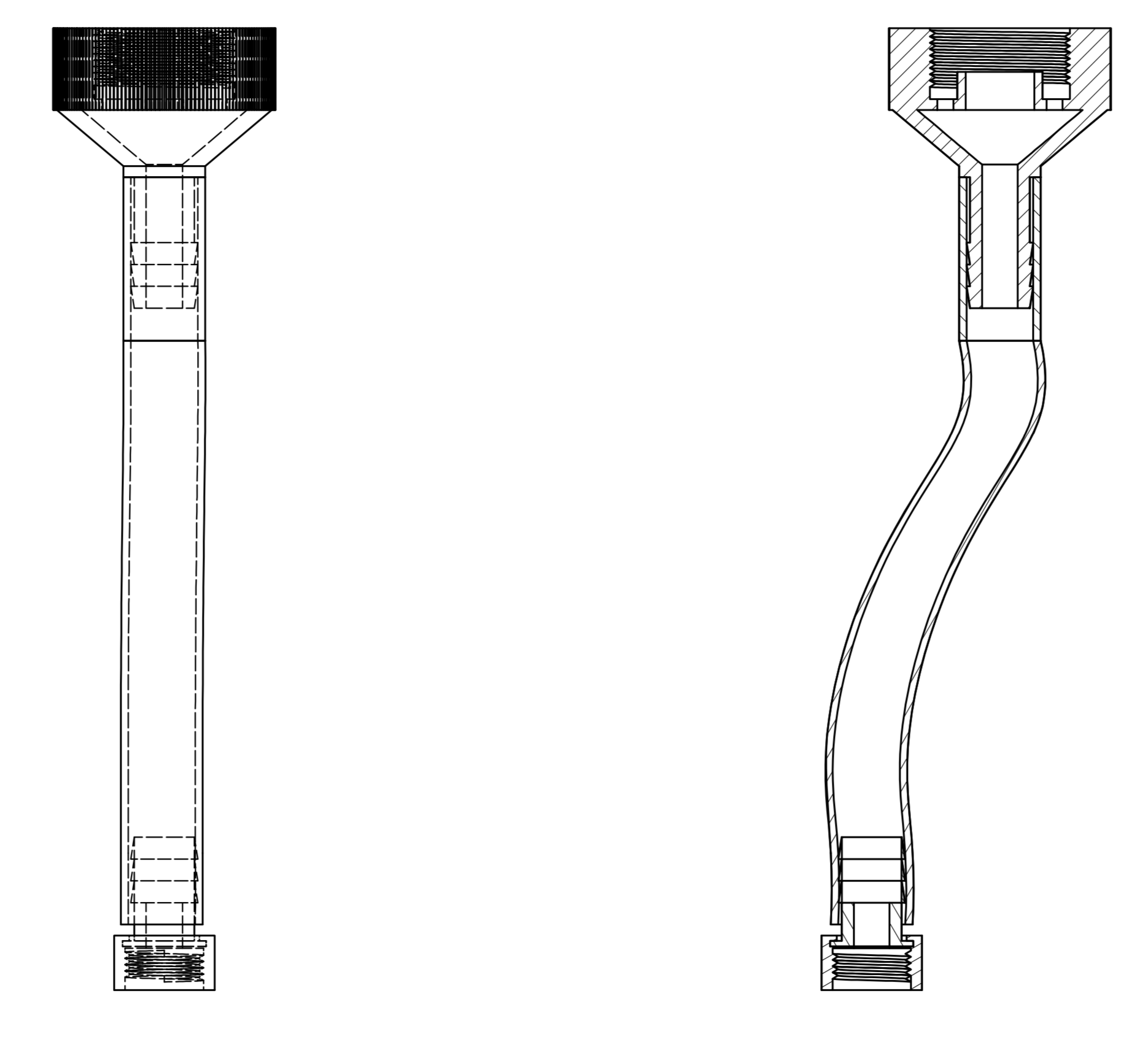

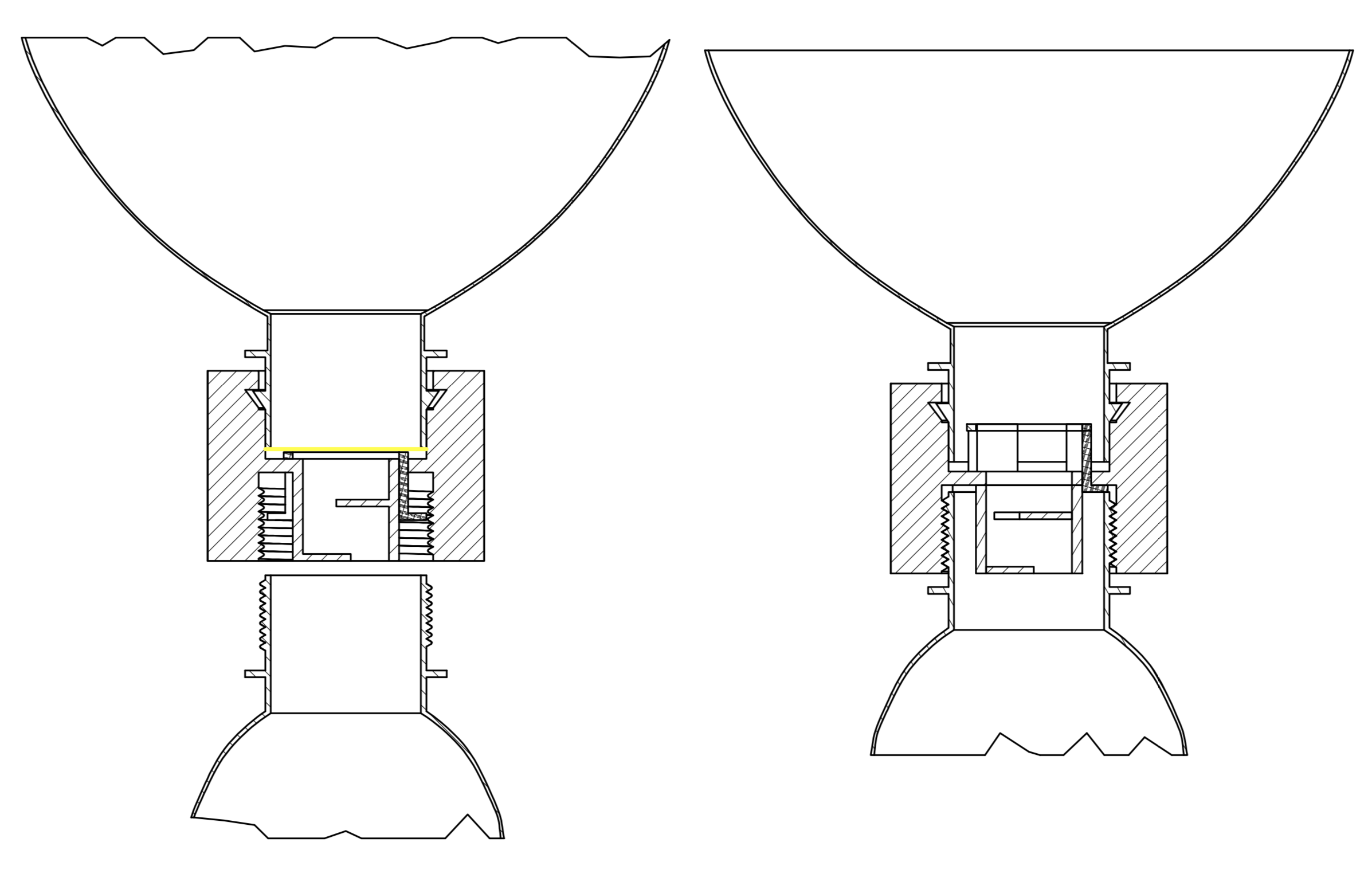

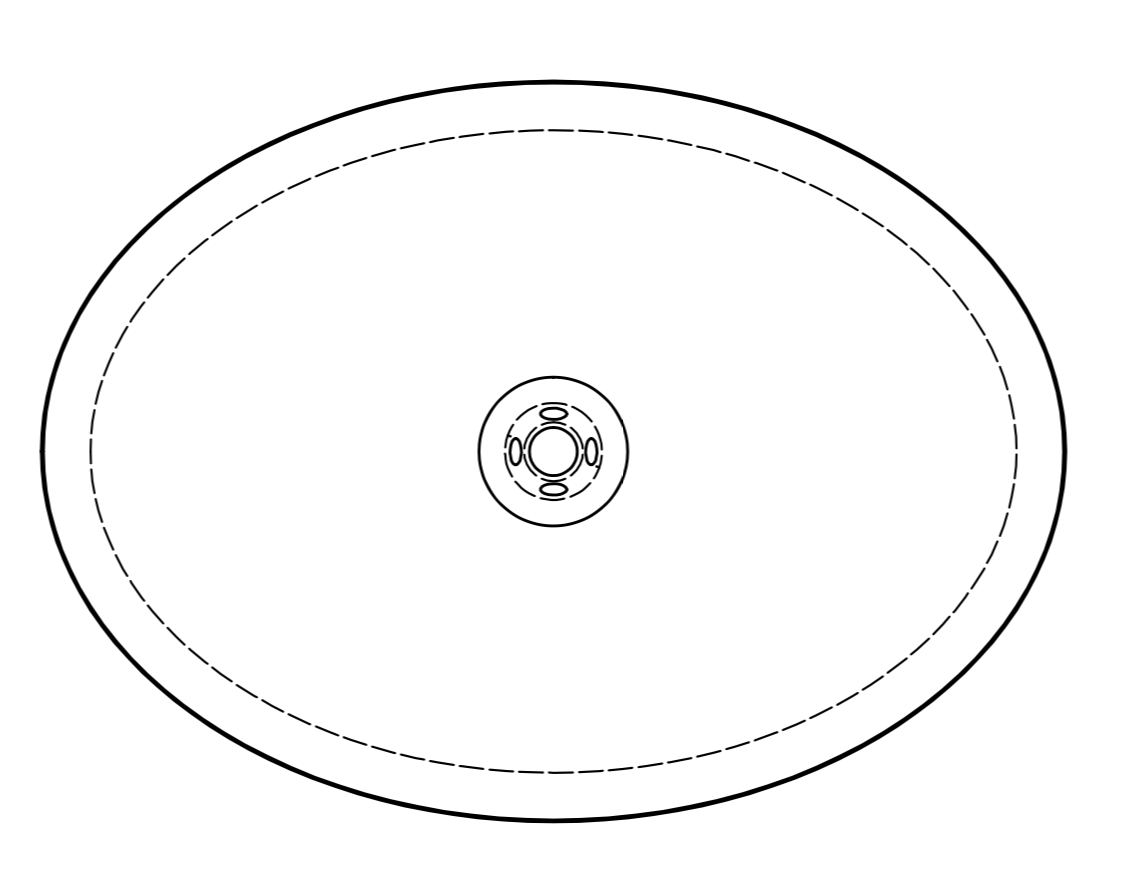

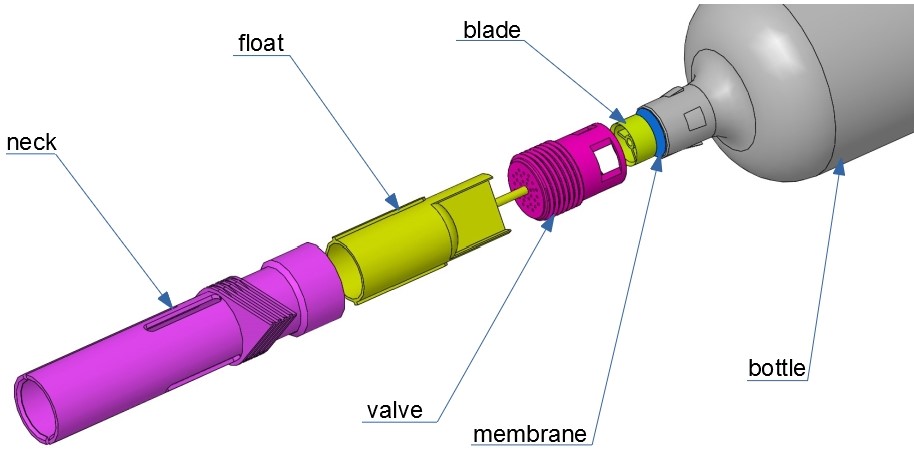

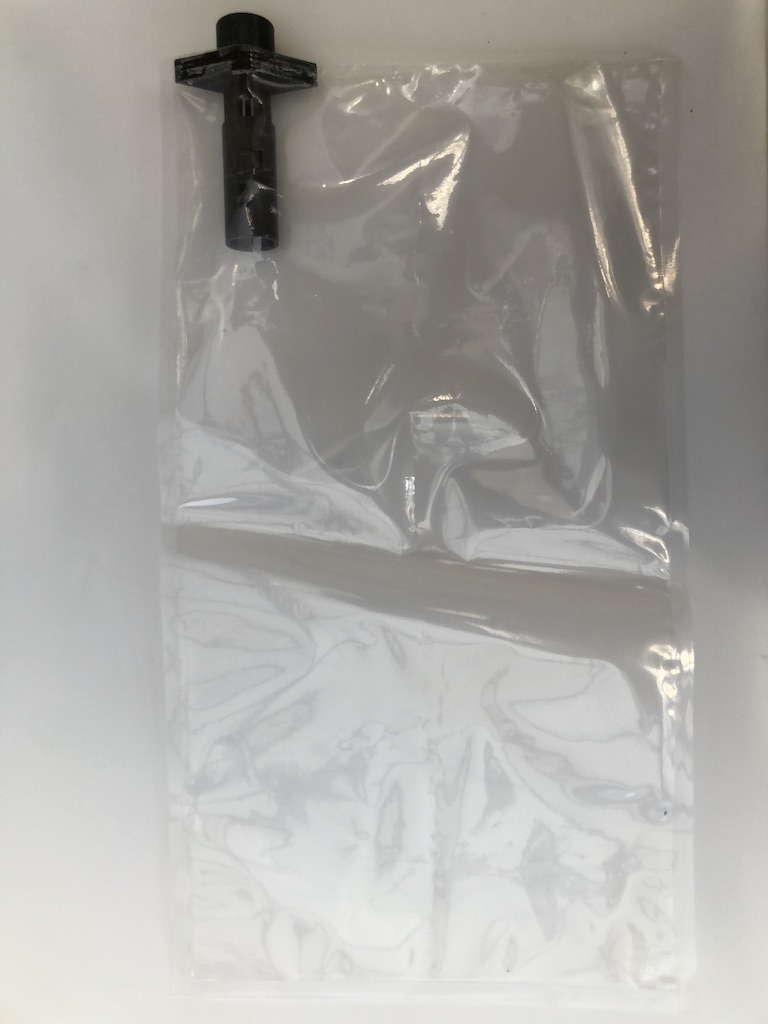

VAR 2.1 DV with locking - this variant that provides the highest level of protection by completely eliminating any contact between the user and the concentrate throughout the dilution process. The system is based on the use of a float placed inside a neck that is part of a pouch.

Dilution procedure: First, the exact amount of water or other liquid with which the concentrate is to be mixed is poured through the neck into the pouch, which raises the float to the desired level. Then, the user fastens the float over the wall of the pouch and turns it with force, thereby locking the float in the desired place. Finally, the container with the concentrate is screwed onto the neck of the pouch. First, the entire system is screwed closed to seal. Then, a needle located at the top of the float and in the centre of the neck penetrates into the valve, which covers the membrane (the valve cannot be removed from the container). Inside the valve, there is a peripheral knife that cuts through the membrane.

The concentrate flows through it and the valve into the lower pouch, where it is mixed with water or another liquid. After the dilution process, the top container is unscrewed - the application solution is ready for use.

However, the application solution can be stored in the bag, which can be closed with a stopper that comes with the product.

It is favourable to supply the entire product package to the market in a box containing a bottle equipped with a dilution valve, an empty bag and a stopper for closing the bag after the dilution process. Another advantage is the possibility to print the bag with any text or picture or a measuring line for the precise determination of the level before dilution.

This is mostly used by non-professional users when diluting corrosive biocidal products or products that are hazardous in another way. This dilution valve variant will be tested according to EN ISO 8317 (child-resistant packaging).

VAR 2.2 DV without locking - a dilution valve variant that is almost identical to the dilution valve with locking. The difference is that the user does not turn the float sideways to lock it, but presses it from opposite sides at a designated point, making it easier to lock the float. This dilution valve variant will also be tested according to EN ISO 8317 (child-resistant packaging).

VAR 2.3 DV with a handle outside of the dilution container - the last dilution valve version that uses a float inside a pouch differs from the previous ones in that the float is locked by a handle on the neck outside of the container in which the liquids are mixed.

The picture on the left is for demonstration purposes only as pouches are usually opaque and printed with e.g. pictures, texts, instruction for use, safety symbols, P+H phrases of the diluted concentrate, etc. Pouches also include a measuring line on the side for the accurate measurement of water in an otherwise opaque pouch.

All technical solutions are patent pending.